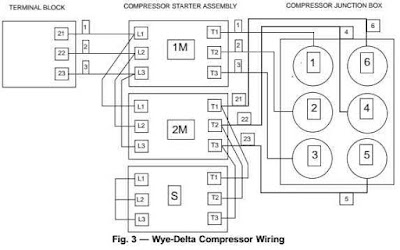

Download Carrier 30GX Service Manual PDF is the primary document used for repairing, troubleshooting, disassembly, reassembly. This Carrier 30GX Service Manual describes safety considerations, major system components, processor module (PSIO-1), DSIO-HV relay module, compressor protection module (CPM), PSIO-2 (8052) module, keypad and display module (also called HSIO-II), control (LOR) switch, operation data, electronic expansion device (EXD), oil pumps, motor cooling, back pressure valve (30GX and 30HXA only), sensors, compressor protection module (CPM), wye-delta vs across-the-line (XL) starting option, capacity control, head pressure control, cooler and condenser (30HXC) pump control, cooler heater control, keypad and display module (also called HSIO-II), temperature reset, demand limit, troubleshooting, checking display codes, unit shutoff, complete unit stoppage, single circuit stoppage, restart procedure, alarms and alerts, compressor alarm/alert circuit, EXD troubleshooting procedure, servicing coolers and condensers, refrigerant charging/adding charge, replacing defective processor module.

The Carrier 30GX has a compact design that is up to 50% smaller than existing coolers. The Carrier 30GX is supplied as a complete package for easy installation. The 30GX also provides a single electrical input (using the optionally installed on factory installed power transformer or an accessory field) and quick and easy pipe using clamp couplings type VIC standard aulic or welded standard for the cooler. Ensures a quick start commissioning after installation, since each unit 30GX is manufactured in an ISO 9002 listed manufacturing plant to guarantee the quality. In addition, all units are factory full load testing to provide a setting up reliable. 30GX units have a design quiet, low-vibration with compression screws rotating and new "aero-acoustic" fans that reduce sound levels and improve the quality of the sound.

The Carrier 30GX controls are fully automatic. Output fluid temperature is controlled directly, and the fluid inlet temperature is continuously monitored to detect changes of load and flow. This combination (an exclusive advantage of Flotronic controls) provides temperature control more precise available. In addition, 30GX units can handle fast and slow loading applications. All coolers air-cooled 30GX with ECOLOGIC controls are ready to connect them to the network Carrier Comfort Network (CCN) systems or can be used in independent operations. In addition, with the standard accessories control module, ECOLOGICAL coolers can accept signals limit demand, point dual setpoint and temperature of outside air through a connection of 4 to 20 mA, which makes them ideal for applications of feedback with an existing building management system.

Download Carrier 30GX Service Manual here

0 Response to "Carrier 30GX Service Manual"

Post a Comment